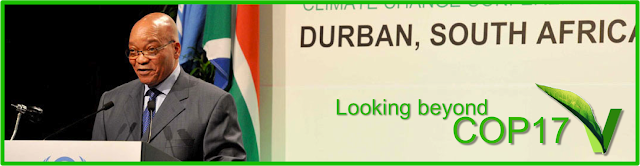

As Durban, and the rest of the world, reflects on the Conference of the Parties’ 17th Climate Change Conference 2011 (COP17) that was held last week, it’s easy to say that not much was done. The Kyoto Treaty, which was on the cards as a massive topic for debate, has been extended another six years, and will be up for review in 2017, with it’s expiry set for 2018.

America, Japan and Australia all found enough wriggle room to avoid confronting their non-adherence to reducing their carbon emissions to the agreed amount and many other discussions were held that served to inform, more than incite change.

But the bigger picture is this: the world is concerned and South Africans were made aware of the weight and intent of the international players to unite and build a future that is sustainable for destined generations.

As a passionate and devoted green builder, Vexiflex is not sitting around and waiting until politicians and tree-huggers agree; we believe that the world is already behind in protecting and looking after our environment. The oldest instruction to mankind was to ‘tend the garden’, and we understand this to mean that we need to be responsible with what we have in a way that will provide more for others.

But the bigger picture is this: the world is concerned and South Africans were made aware of the weight and intent of the international players to unite and build a future that is sustainable for destined generations.

As a passionate and devoted green builder, Vexiflex is not sitting around and waiting until politicians and tree-huggers agree; we believe that the world is already behind in protecting and looking after our environment. The oldest instruction to mankind was to ‘tend the garden’, and we understand this to mean that we need to be responsible with what we have in a way that will provide more for others.